WAAM Powder Feeder

(Wire-Arc Additive Manufacturing — Modular Powder Feeder attachment)

Skills

SolidWorks CAD, SolidWorks Simulation (FEA), Mechanical Integration, Resin 3D Printing, Assembly & Test Rapid Iteration

Objective

Design a powder feeder attachment that mounts to a WAAM robotic arm and MIG torch system to enable continuous fabrication of large metal-matrix-composite (MMC) parts—without disrupting the existing print process.

Key System Requirements

Overall System

- Deposition rate: 10 g/min powder deposition

- Mass: < 20 lb total assembly

- Heat environment: withstand ~1500 °C melt-pool proximity (radiant exposure)

- Integration: no impact to WAAM torch operation or robot motion envelope

- Manufacturability: fabricated quickly enough for quick testing and rapid iteration

Mounting

- Load support: powder feeder + existing camera system

- Serviceability: install/remove by a single person during iterative testing

- Clearance: no interference with robot travel or torch operation

- Vibration robustness: resist loosening / preserve feeder position during motion

Design Process

I approached the mount as a practical integration task: it had to hold alignment through robot motion, not interfere with the torch and existing cables, and be able to be installed and removed quickly during iterative testing.

- Defined constraints & failure modes. Clearance uncertainty near the torch, robot motion/vibration, and the risk of interference during travel were the main integration risks. Success meant consistent positioning and quick and easy serviceability.

-

Reverse engineered the torch head for accurate CAD interfaces.

Due to limited documentation I figured the best first course of action was to measure the WAAM torch head with digital calipers and built a full-scale SolidWorks model to lock down clamp surfaces,

fastener locations, and cable/torch clearance.

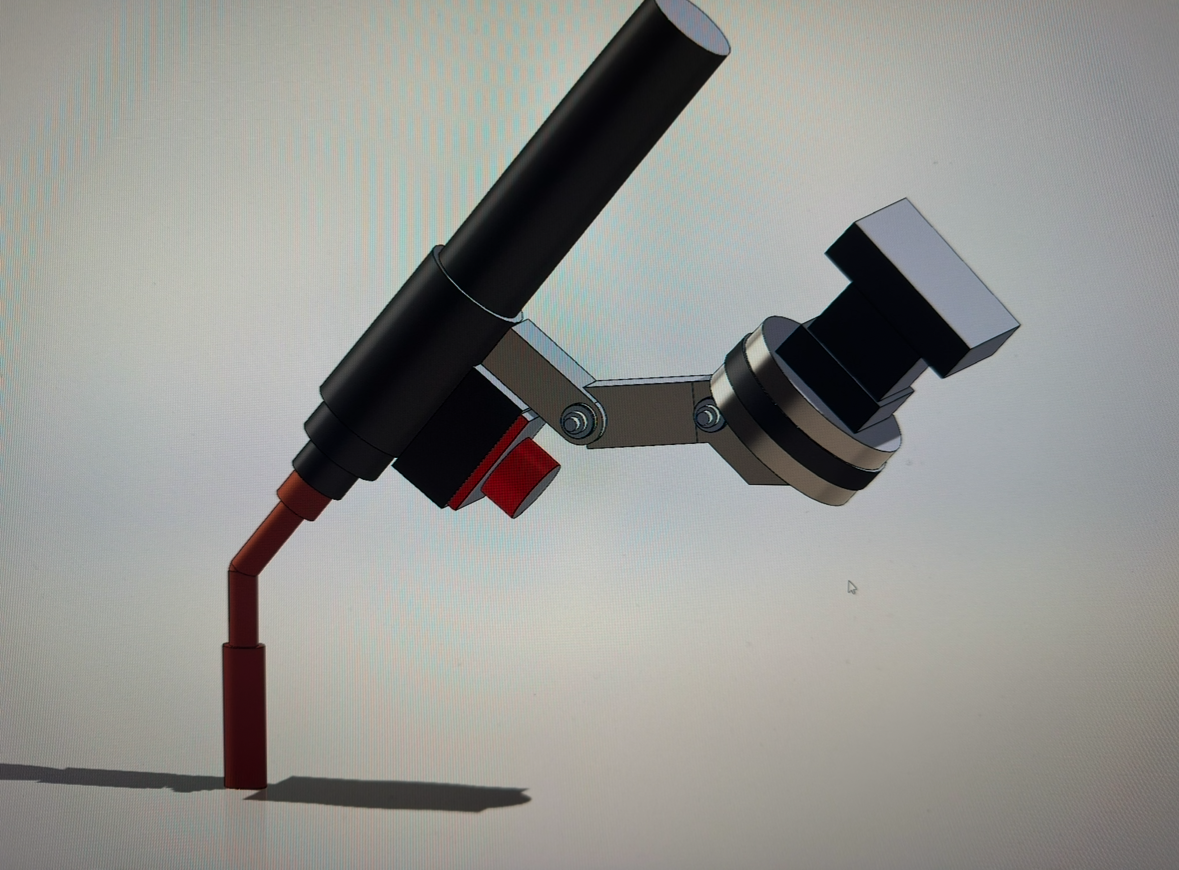

My Full-scale torch reference model used to design clamp geometry and ensure clearance. -

Designed a rigid, repeatable clamp-style mount.

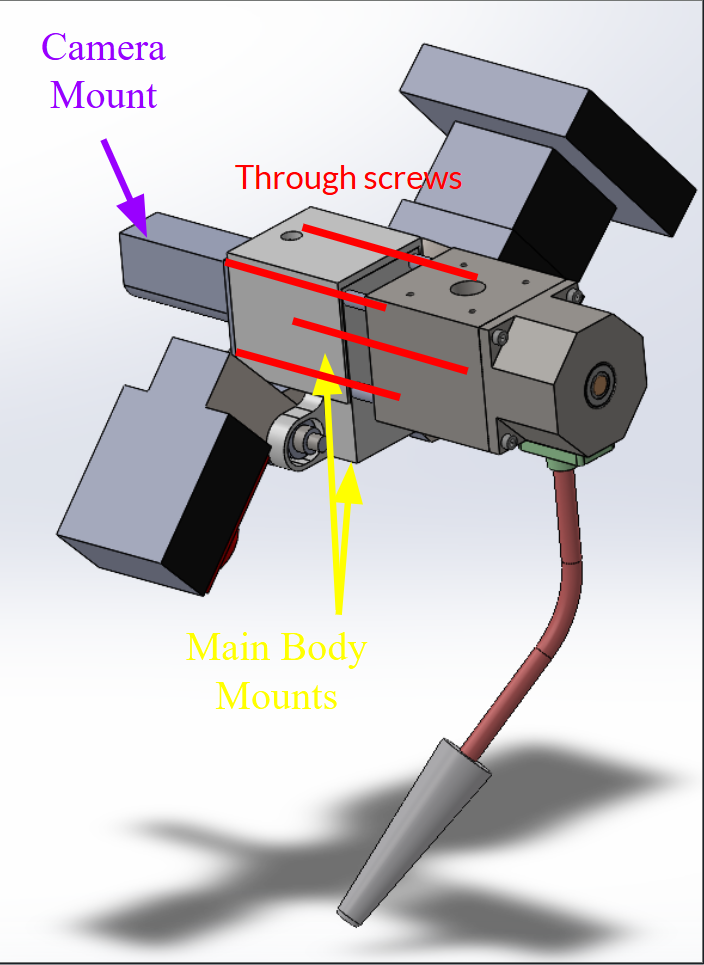

I designed the mount to position the feeder consistently relative to the torch while preserving the pre-existing camera mount.

Hardware selections included stainless M5 fasteners with split lock washers to reduce loosening, and M8 nuts

to secure to existing M8 torch-head fasteners.

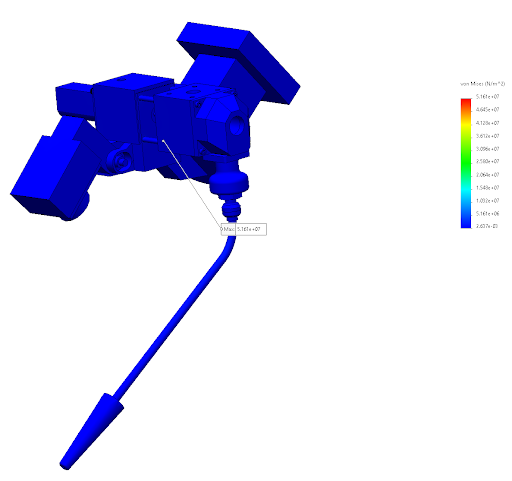

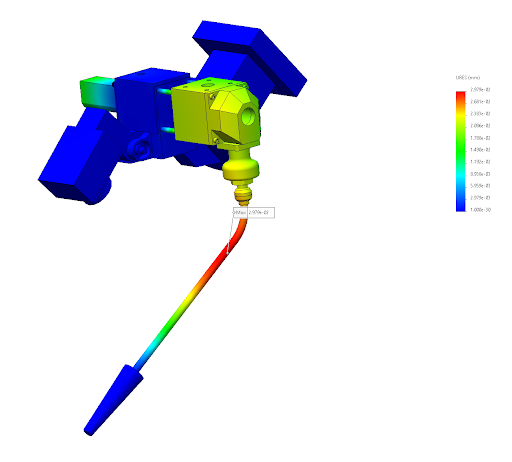

Mounting concept showing primary interfaces and retained camera mount location. - Verified stiffness and safety margin with full-assembly FEA. Before printing, I ran SolidWorks Simulation on a simplified assembly of the powder feeder to evaluate deformation/stiffness and ensure no obvious high-risk stress concentrations in the mount or interfaces under expected loading.

-

Fabricated, assembled, and validated fit on hardware.

I resin 3D printed the final mounting parts with a Formlabs 3L resin printer, checked fit on the physical torch, and assembled the powder feeder onto the robot.

I validated clamp security and confirmed the setup was practical for repeated use.

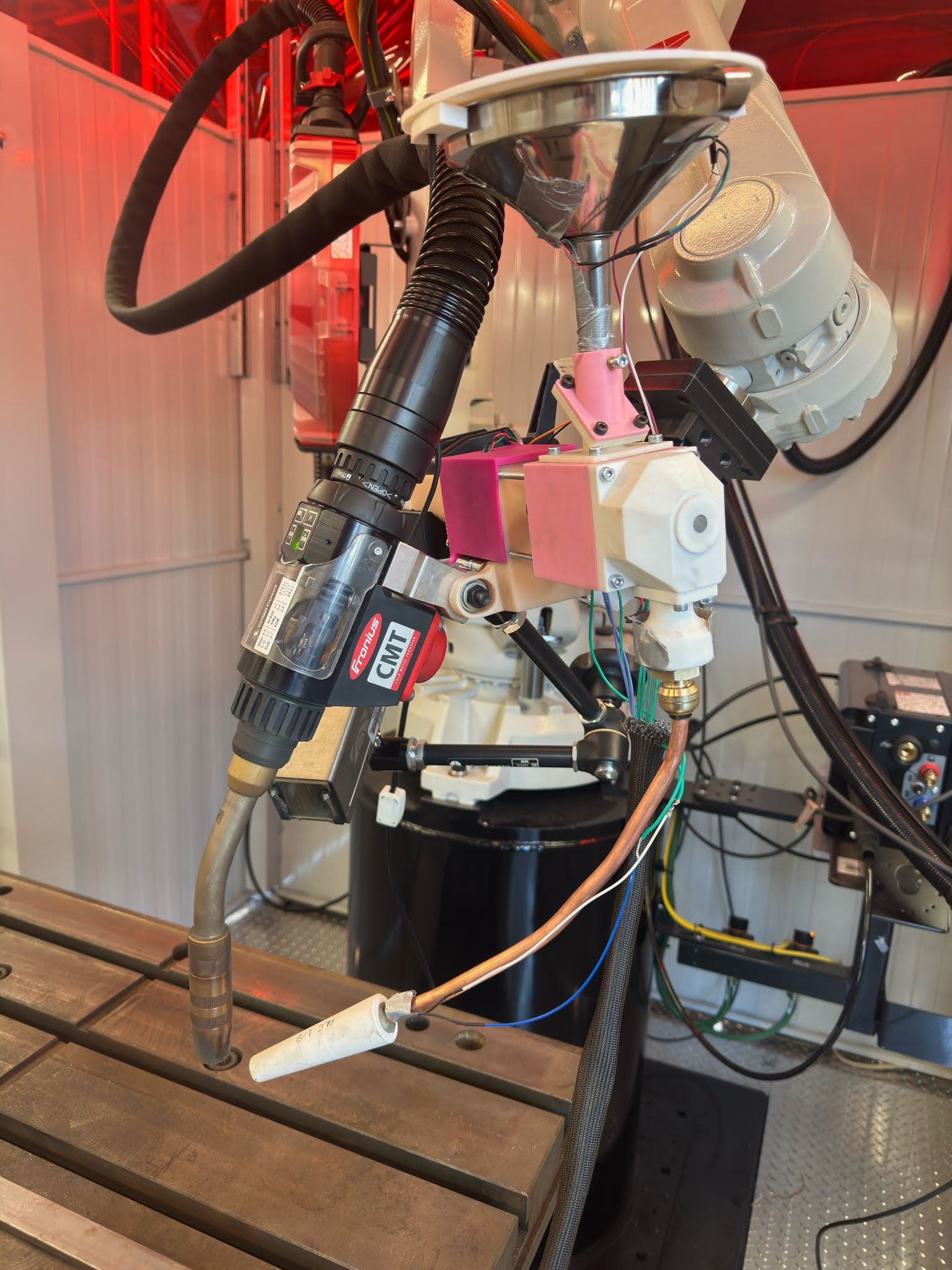

Final assembled mount installed on the WAAM torch/robot system. - Testing & iteration support. I designed the mount for quick removal and reinstallation so we could iterate during tuning without modifying other WAAM hardware. Before final testing, I ran a shake-down motion test—driving the robot through aggressive movement profiles—to confirm there was no interference and that the powder feeder remained secure with no loosening.

Results

- Successfully mounted the powder feeder to the WAAM system using a custom resin-printed mount and selected assembly hardware.

- Maintained practical usability: removable/adjustable feeder assembly and preserved the existing camera mounting function.

- Supported robot motion testing without obvious clearance/interference issues.

Final integration test video (mount installed and system exercised).

Supplemental Thermal Analysis

As a separate risk check from the mounting work, I performed a hand-calculation to determine whether the powder delivery nozzle required thermal protection near the WAAM melt pool.

- Method: 3-surface, radiation-only enclosure heat transfer model.

- Key result: Predicted nozzle-tip temperature of 1410.6 °C at a standoff distance of 21.6 cm from the melt pool.

- Engineering decision: Selected a ceramic nozzle to protect the powder feeder outflow from excessive heat exposure.