Triplet-Impinging Fuel Injector for LRE

(Aerospace Northeastern Club)

Skills

ANSYS Fluent, Rocket Fuel Injector Design, Test Planning, NASA CEA, Solidworks

Objective

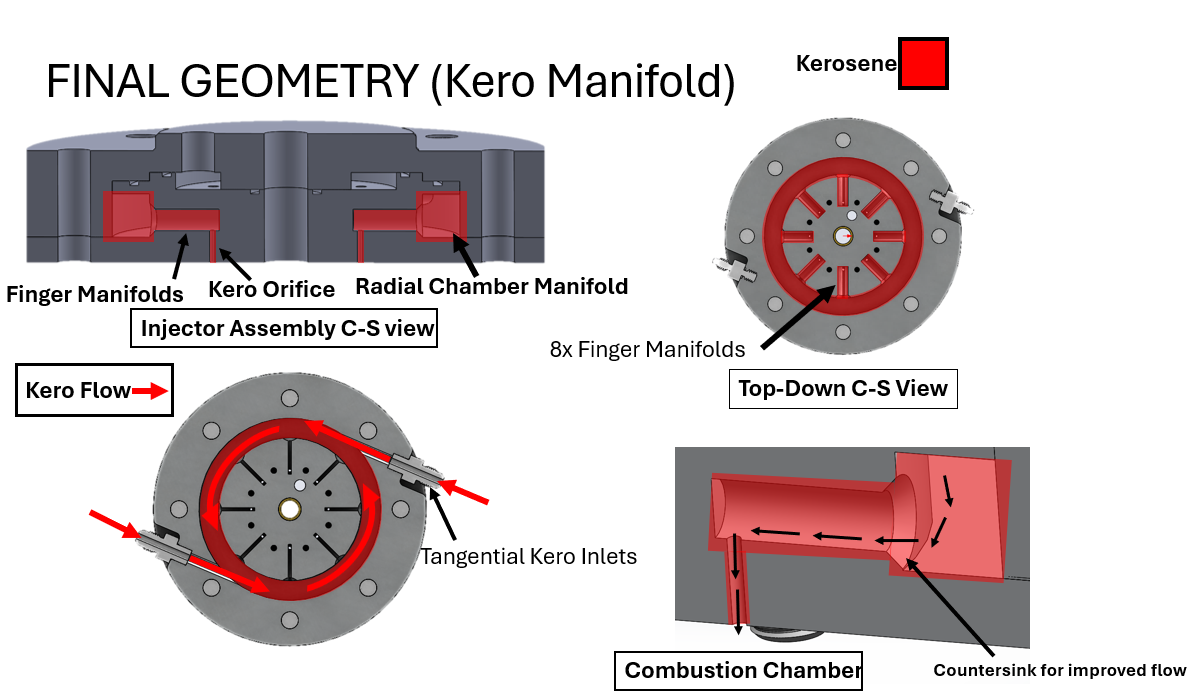

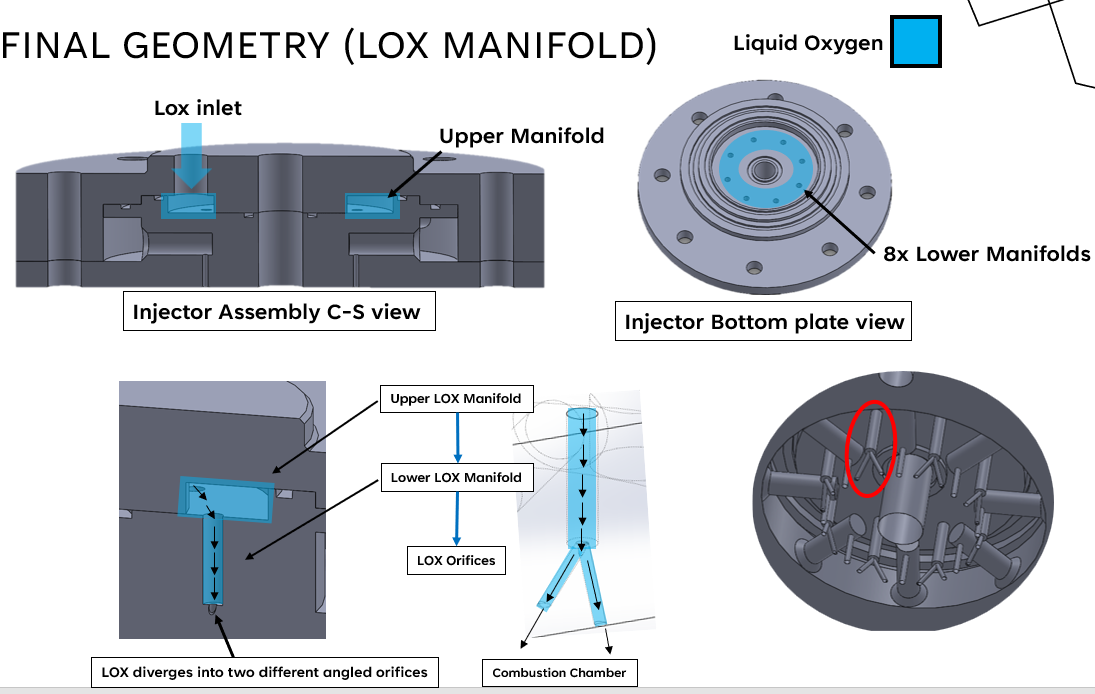

Design a triplet-impinging LOX/Kerosene injector for a liquid rocket engine

Key System Requirements

- Pressure capability: 500 psi outlet, 600 psi inlet

- Thermal environment: Withstand cryogenic and combustion temperatures

- Hard-start robustness: Design and sequencing informed by propellant pooling risk

- Interfaces: -06 AS5202 igniter/ASI port + chamber pressure tap

- Integration constraint: 3-inch combustion chamber diameter

- Manufacturability: Machinable injector geometry

Design Process

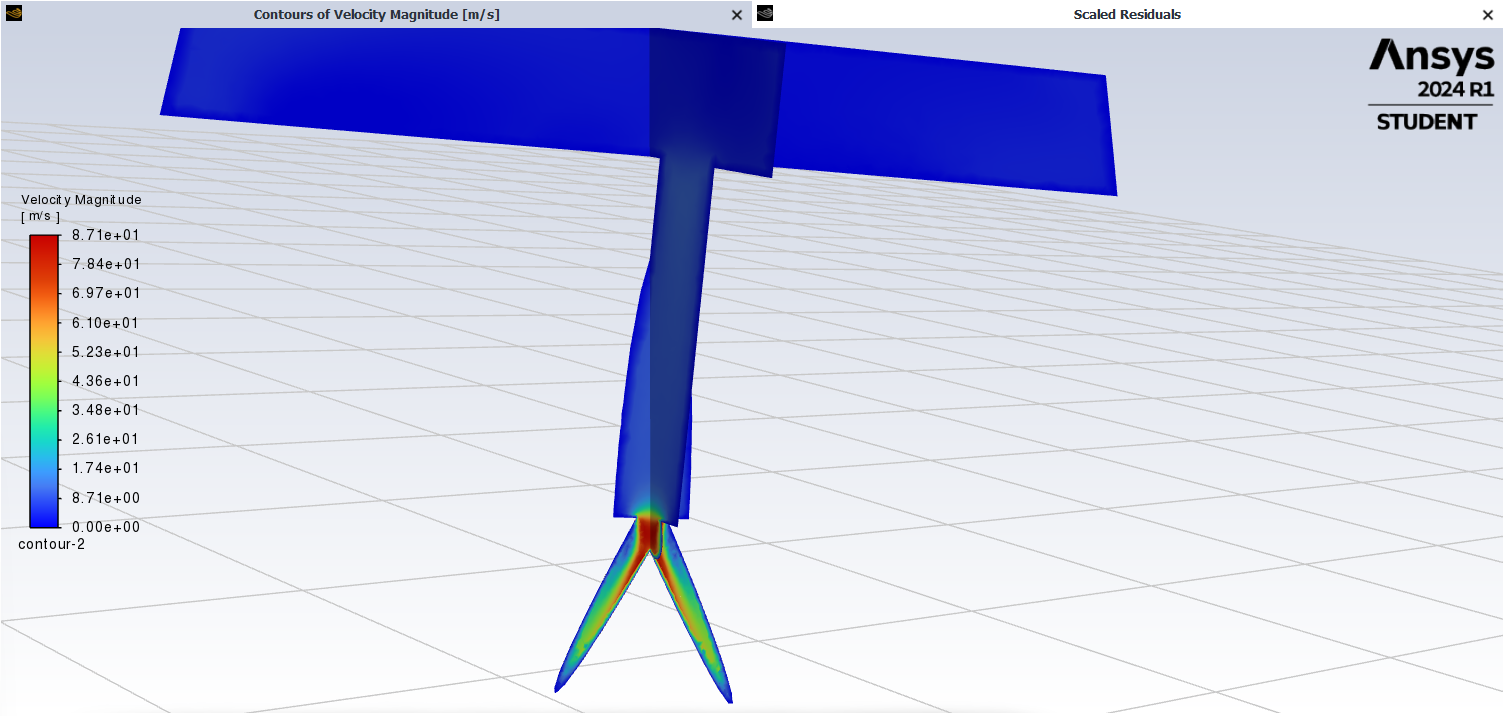

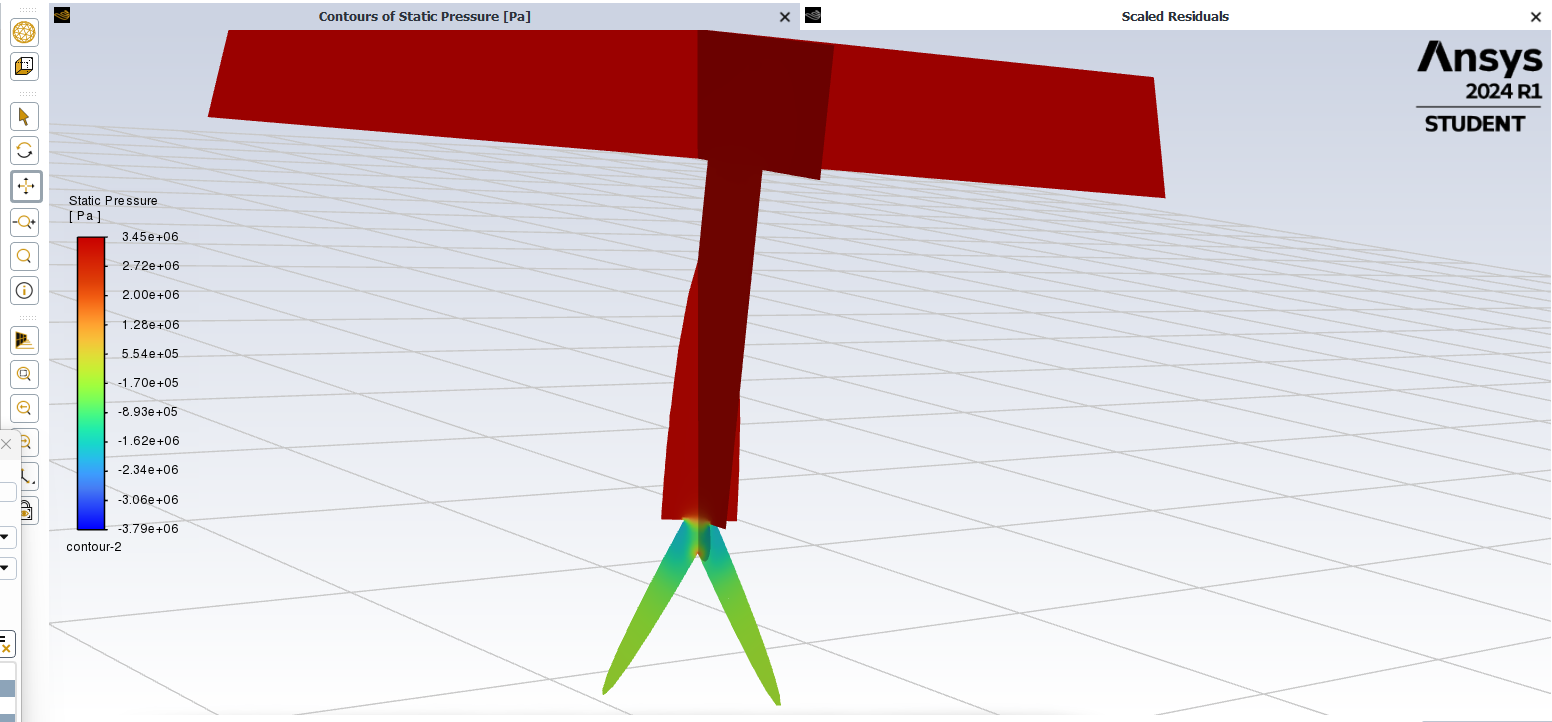

I owned the injector fluid characterization work by running CFD in ANSYS Fluent to understand internal flow behavior and generate preliminary discharge coefficient (Cd) estimates before testing. This let us identify likely losses, confirm flow distribution trends, and de-risk geometry decisions early.

- Model setup: Built Fluent cases to represent the injector flow paths and operating pressure conditions

- Flow behavior: Evaluated velocity/pressure fields to understand restrictions, loss regions, and overall flow characteristics

- Preliminary Cd: Extracted early Cd values from simulated ΔP vs. mass flow behavior to guide initial sizing

- Design feedback: Used CFD results to inform geometry tweaks prior to cold-flow validation

Hard Start Check (Link to Excel Sheet Here)

I created a propellant pooling estimate parametric calculator using NASA's CEA website and my thermodynamics textbook to understand ignition-delay risk and to guide safer sequencing during early testing.

- Assumed pooling time: 0.25 s

- Pooled mass: 0.2235 kg total (LOX 0.1375 kg, Kero 0.0860 kg)

- Mixture ratio: O/F = 1.6 (by weight)

Given the set parameters above I found the internal energy of the entire mixture and was able to plug that into the CEA software using the combustion at assigned density to get the chamber pressure if all the pooled propellant were to combust instantaneously.

Results

Estimated pressure: 94.48 bar (1370.27 psi)

Preliminary Test

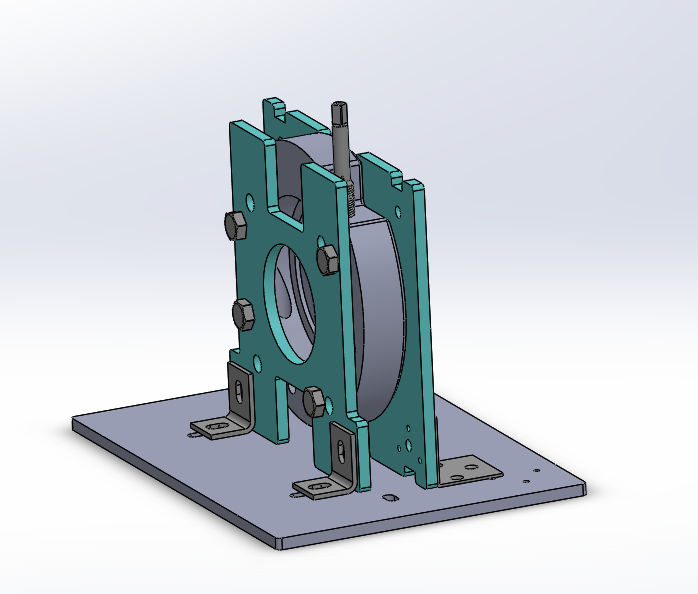

We used dyed-water testing on an SLA-printed injector to verify visible triplet impingement and to confirm that the flow could develop in the tangential finger-like kerosene manifolds.

- Test modes: Hydrostatic (~13 psi from ~30 ft head) and pump-fed (~35 psi)

- Readout: High-speed video (240 FPS, slowed) to confirm a stable “water cone” and impingement behavior

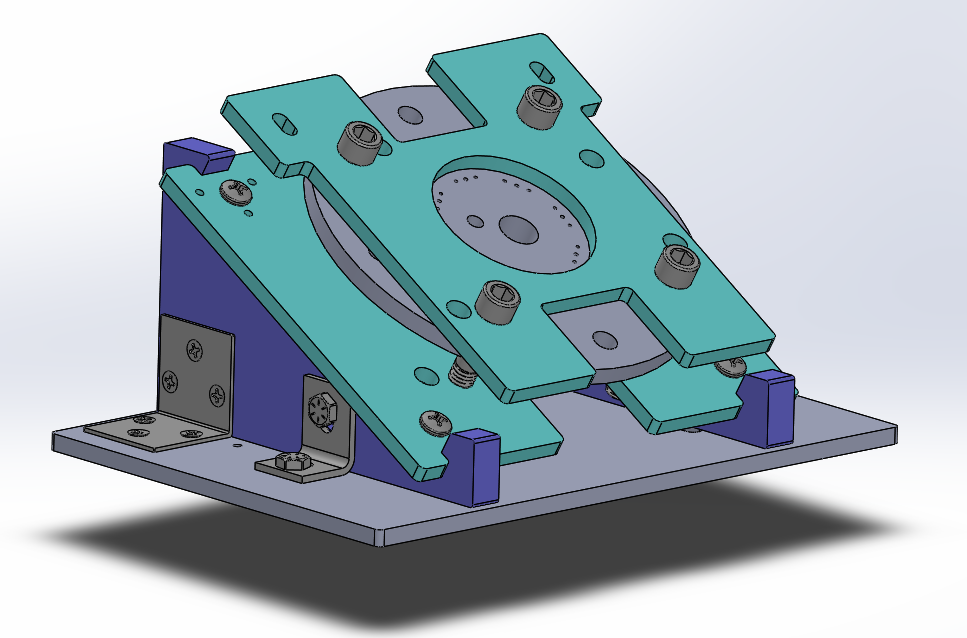

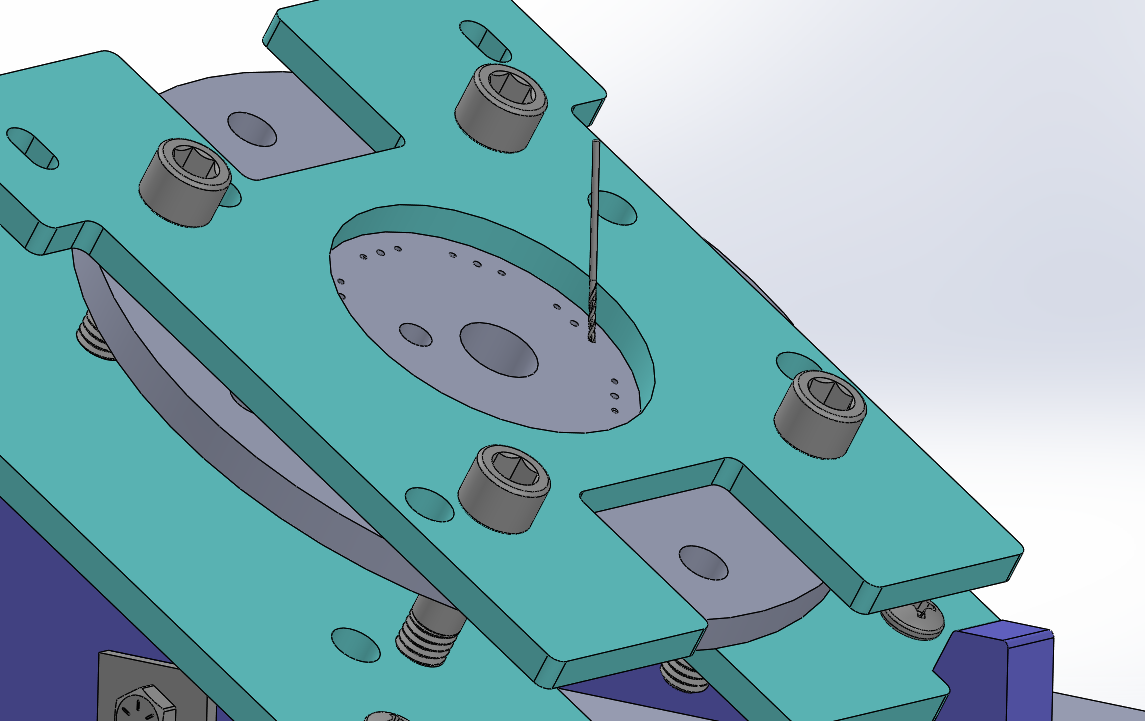

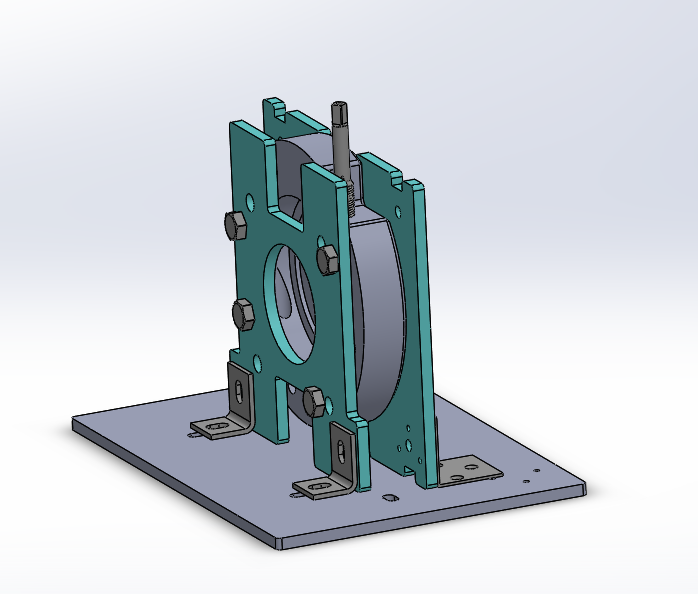

I and one other person jointly made a fixture design to hold the injector during machining of lox and kerosene orifice.

Results

Key outcomes:

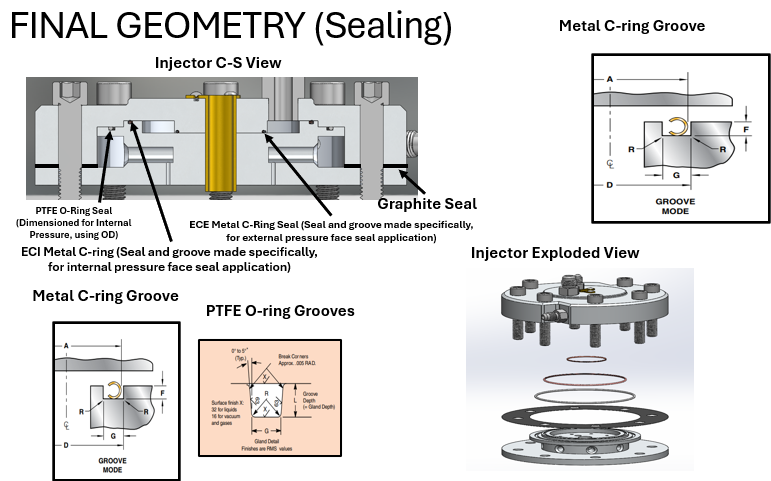

- I completed the injector manifold design for an 8-element unlike triplet impingement fuel injector for a lox/kerosene liquid rocket engine.

- I validated visible triplet impingement behavior with an SLA water-flow proof-of-concept test (hydrostatic + pump-fed), confirming the manifold concept before machining.

- I defined a pump-fed Cd test plan to convert assumed discharge coefficients into measured values and directly drive orifice resizing decisions.

- I added a hard-start pooling estimate to support safer ignition sequencing during early engine development testing.

Hot Fire Test media: