NU London Robotics

(Northeastern University London Campus Robotics Team)

Skills

CAD (Fusion 360), Laser Cutting (DFM), Rapid Prototyping, Robotic Mechanical Design, Packaging Electronics

Key System Requirements

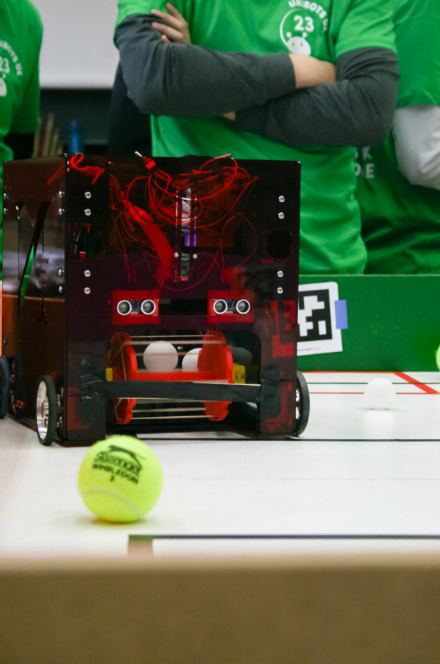

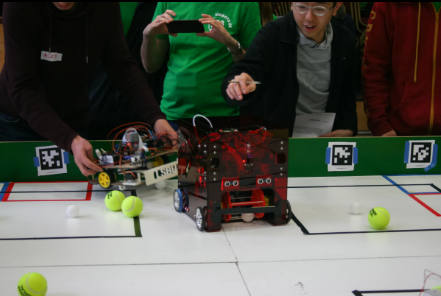

- Match objective: Autonomously collect and store ping pong balls to score within a 3-minute match

- Assembly speed: Laser-cut, flat-panel chassis for quick build + fast iteration

- Durability: Withstand repeated collisions and competition handling (lift in/out of arena)

- Maintainability: Serviceable internal layout with short wiring runs and accessible connectors

- Power system: Secure 12V battery holder with quick-swap access from the bottom

- Stability & traction: Low/centered battery placement to reduce slip and improve turning stability

Objective

Design and build an autonomous robot to collect and store as many ping pong balls as possible within a 3-minute match, competing against three other robots. The design needed to be fast to assemble, durable for repeated matches, and reliable under real competition handling.

Design Process

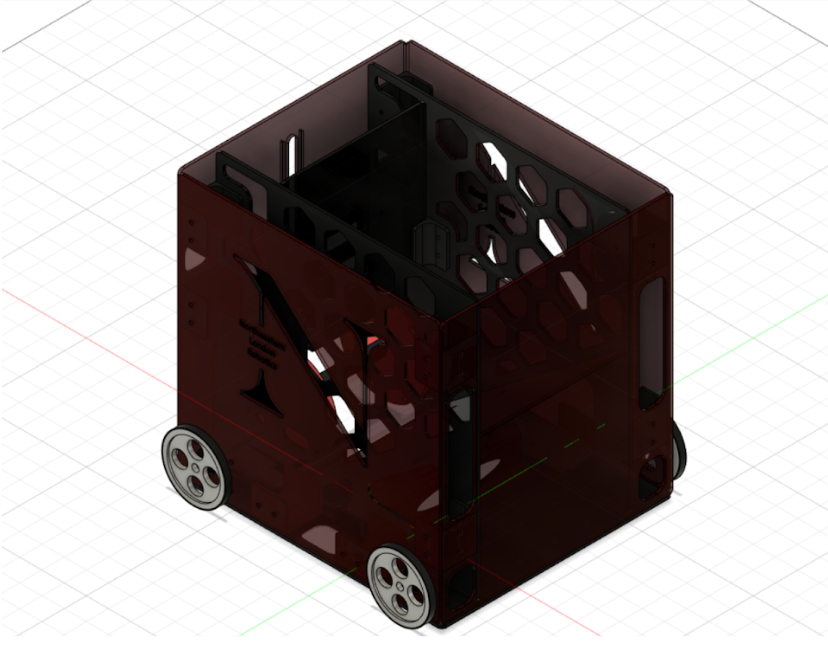

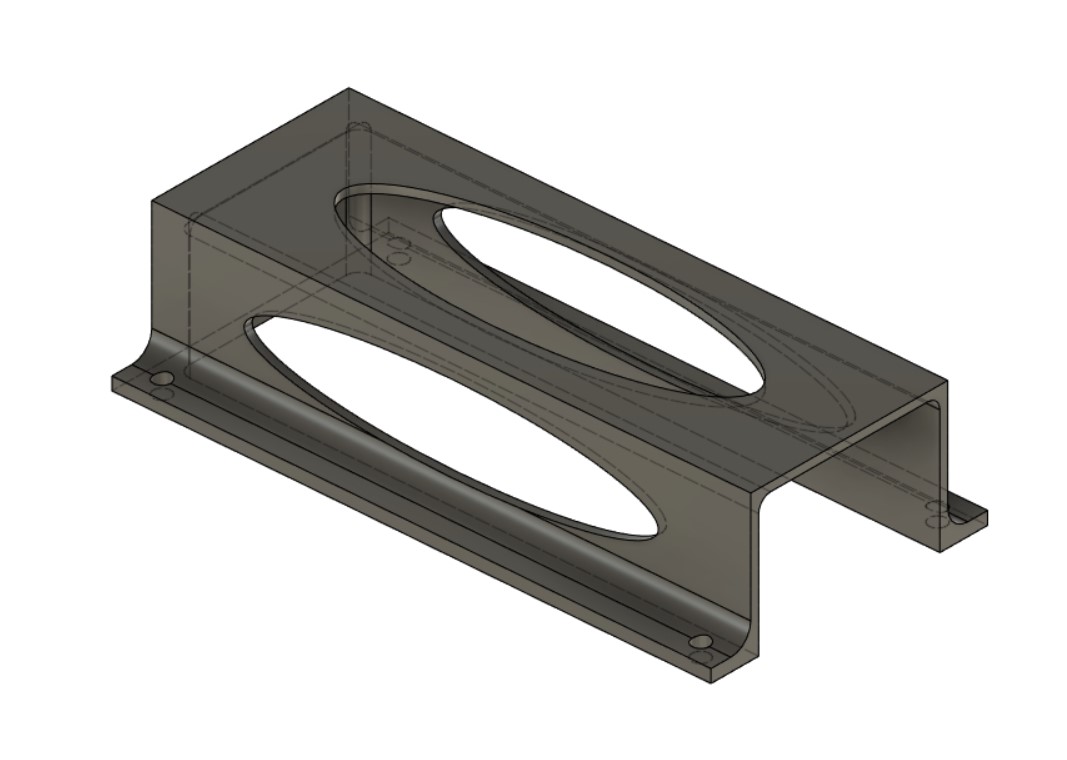

My focus: I owned key mechanical packaging work—designing the electronics + sensor + motor housing and the internal 12V battery holder in Fusion 360, optimized for laser cutting and quick assembly.

- Strategy and trade studies. We started by brainstorming scoring strategies and quickly compared two options: (1) collect and store balls onboard vs. (2) return balls to a scoring zone. We chose onboard storage because it reduced navigation complexity, shortened travel distance, and lowered risk of losing points due to pathing errors.

- Mechanical concept for speed and reliability. From a mechanical standpoint, we needed a chassis that was: (a) rigid enough to protect electronics, (b) simple to assemble, and (c) easy to iterate quickly. We decided on laser-cut panels (flat-pack style) to reduce machining time and enable fast redesigns.

- My contribution: electronics + sensor + motor packaging. I designed the housing that organized the electronics, sensors, and motors so wiring runs stayed short, connectors were accessible, and components were protected during collisions and handling. My goal was to make the internal layout “serviceable”: if something failed, we could access it quickly without disassembling the entire robot.

- My contribution: 12V battery holder design. I designed the internal 12V lithium-ion battery holder and chose its placement intentionally: centered low on the robot to improve stability, and positioned away from sensitive electronics to reduce damage risk and simplify cable routing. I also designed it to be accessible from the bottom with a protective cover so the battery could be swapped quickly between matches.

- Prototype build (proof of concept). We laser-cut the first chassis panels from 1/4" plywood to validate clearances, fit-up, and basic functionality. This material choice let us iterate quickly and cheaply before committing to a cleaner final build.

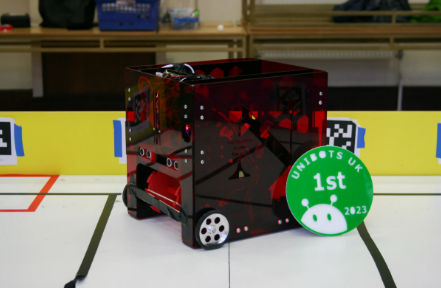

- Design iteration and final material. After validating the plywood prototype and confirming assembly order + access points, we re-cut the panels in acrylic for improved stiffness, consistency, and a cleaner finished build.

- Challenge: wheel slip / low traction. During early testing, the wheels slipped under acceleration and while turning, which reduced navigation accuracy. We treated this as a system-level issue (traction + weight distribution + surface interaction) and adjusted setup to improve grip and reduce slip.

- Challenge: lift-point failure (panel cracking). A real-world handling failure showed up when the robot was lifted out of the arena: the top of a side panel snapped because it was unintentionally acting as the primary lift point. The fix was to redesign the side panels with dedicated lift features (slot openings near the bottom) so the robot could be lifted from a stronger, more supported area.

- Why this mattered. These failures were valuable because they exposed “competition realities”: not just how the robot drives, but how it survives repeated handling, impacts, and quick turnarounds between matches.

Results

Key outcomes:

- Built a fully functional autonomous robot capable of navigating the arena, collecting ping pong balls, and storing them onboard to score efficiently.

- Achieved 1st place at the Unibots UK competition with a design focused on reliable mechanics, fast assembly, and maintainability.

- My mechanical packaging work (electronics/sensor/motor housing + 12V battery holder) improved robustness, reduced service time during testing, and enabled rapid iteration under competition deadlines.

Challenges overcome & what changed:

- Wheel slip / low traction: Early testing showed slip under acceleration and turns, reducing navigation accuracy. We improved grip by adjusting traction setup and weight distribution.

- Lift-point failure (panel cracking): A side panel cracked when it became an unintended lift point during handling. We redesigned the side panels with dedicated lift slots near the bottom so the robot could be lifted from a stronger region.

Future improvements:

- Traction: Further tune wheel material/traction strategy to improve repeatability across surfaces.

- Durability: Add reinforcement around high-stress panel features and handling interfaces.

- Serviceability: Continue improving access points for faster swaps/repairs between matches.